In the complex world of hospital design, the Central Sterile Services Department (CSSD) often stands out as an intricate but vital element. As architects and builders dedicated to crafting efficient healthcare environments, it’s essential to understand the role of the CSSD in a hospital’s day-to-day operations. The CSSD is not just a department; it’s a hub where sterilization of medical equipment takes place, ensuring that every patient receives care with the utmost safety.

Planning and designing for the CSSD involves a nuanced understanding of various factors, including workflow, equipment needs, spatial requirements, and adherence to stringent standards. In this comprehensive guide, we will delve into the key principles of CSSD design, offering insights and practical solutions that align with contemporary healthcare demands. Whether you are embarking on a new hospital project or looking to renovate an existing facility, understanding the CSSD is an indispensable part of the process, one that can enhance both operational efficiency and patient care.

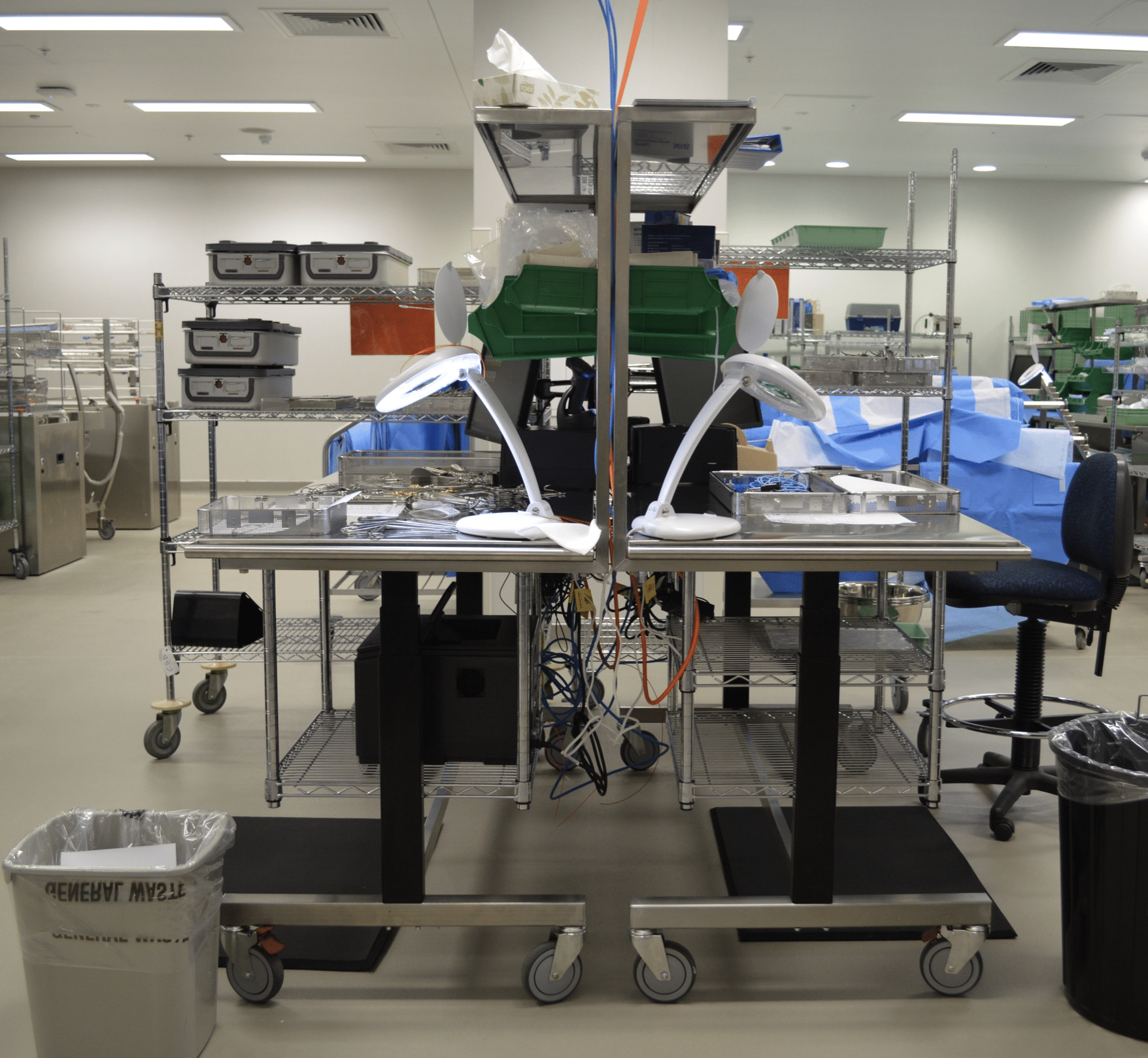

The CSSD department must prevent cross-contamination. A unidirectional workflow is vital. This guides instruments from dirty to clean to sterile. The goal? Minimize risk and boost efficiency. Meticulous planning and understanding of the layout are key. Every space, including entrance zones and sterilizing areas, must be organized. This ensures a contamination-free workflow. Need CSSD products that suit this workflow? Collaborating with experts can help with safety and efficiency.

Compliance with AS/NZS 4187 isn’t just legal. It’s essential for success. CSSD products must align with these standards. This builds a framework for safety and efficiency. How to comply? Start with the guidelines. Extend to certified consultants who know healthcare regulations. This precision will guide your project right. For a deeper understanding of Australian healthcare standards, you can visit this page

The CSSD department changes with technology. Integrating the latest sterilization CSSD products is vital. Understanding specifications and fitting them into the existing layout is key. How can this be done? By thinking ahead and looking at future trends. Engaging with suppliers and engineers helps design adaptable spaces. This makes a flexible, future-ready CSSD department.

Environmental stewardship is key today. Architects and builders must think differently. An eco-friendly CSSD is about more than trends. It’s about a sustainable future. CSSD products should be energy-efficient and reduce waste. This aligns your CSSD project with green healthcare. Working with experts and using best practices helps meet current demands and global responsibility.

Need CSSD products for the CSSD department in your next hospital project? Explore Emery Industries’ selection tailored for you.

The process of crafting a CSSD within a hospital setting is intricate, but it’s made manageable through the flexibility to adapt to emerging technologies. The CSSD isn’t merely a component within the hospital; its pivotal role in ensuring safety and efficiency demands thoughtful planning and execution. By adopting and integrating these principles, you are poised to construct a superior CSSD department, making it a standout example of success in the field of hospital construction.

Questions about your project? Talk to our sales team. We’re eager to assist in crafting an efficient and innovative design for the CSSD department in your next hospital project.

References