The $314 million redevelopment of The Queen Elizabeth Hospital (TQEH) represents one of South Australia’s most significant modernisation projects in emergency, surgical and critical care. The new six-level clinical services building delivers state-of-the-art environments for both patients and clinicians, including a 46-bay Emergency Department, 12 operating theatres and a suite of specialised units designed for a rapidly growing community.

To support this transformation, the project required medical equipment that matched the scale, complexity and performance standards of a next-generation healthcare facility. This is where Emery Industries played a critical role.

Industry: Healthcare / Hospital Infrastructure

Location: Adelaide, South Australia

Project Value: $314 million

Client: The Queen Elizabeth Hospital (TQEH)

Emery Industries was engaged to design and supply a comprehensive package of stainless-steel medical equipment built specifically for TQEH’s clinical workflows. Each product was engineered for durability, cleanability and seamless integration into the hospital’s new sterile and surgical environments.

Our contribution included:

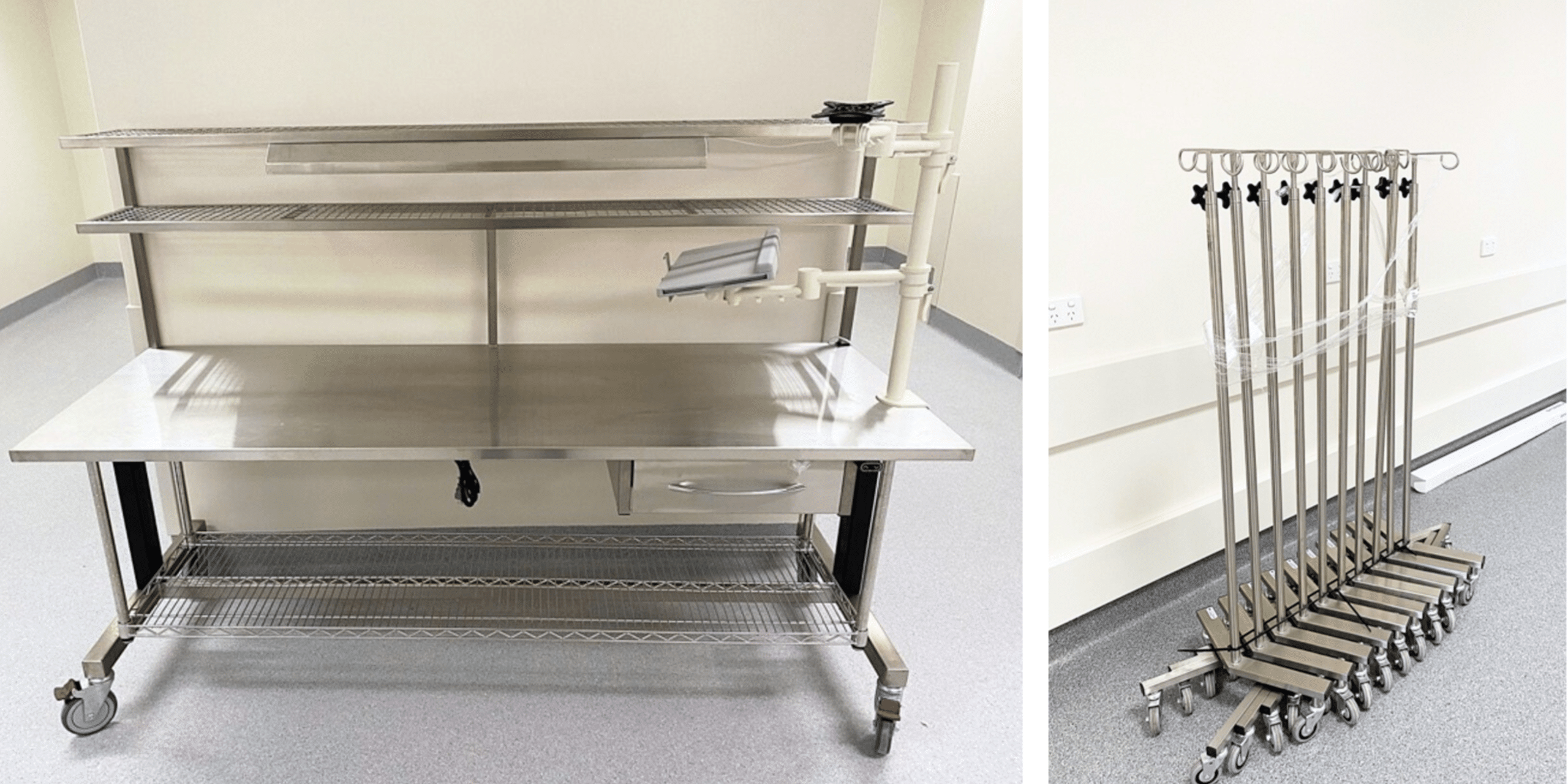

SP398.15 – CSD Case Cart compatible with advanced trolley wash systems

SP430.22-TRW – Genesis Tin Trolley, supporting sterile packaging and instrument handling

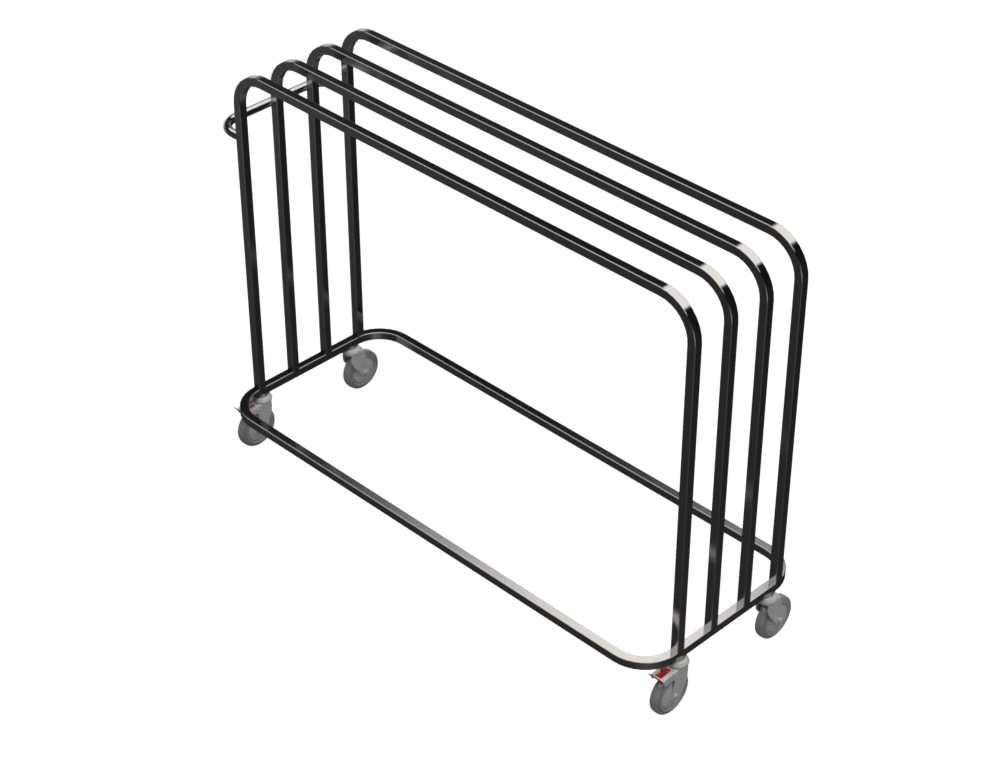

SP440.3 Wrap Rack, improving storage efficiency

CSSD Package, delivering high-performance solutions for sterile services

Trolley Package, a wide range of medical-grade trolleys designed for patient care, logistics and workflow optimisation

These solutions were built to exact specifications, ensuring they met the stringent operational, compliance and infection-control requirements of a major tertiary hospital redevelopment.

Large healthcare redevelopments demand more than off-the-shelf products—they require equipment that aligns with architectural constraints, evolving user needs and live construction schedules.

Throughout the TQEH project, Emery Industries demonstrated agility and proactive project support. This included rapid design adaptation, alignment to construction sequencing and the ability to respond to last-minute user-driven changes without compromising timelines.

The outcomes were clear: improved sterile services processes, safer equipment handling, and enhanced movement of instruments and supplies throughout the facility.

This level of responsiveness ensured that no part of the sterile workflow installation became a bottleneck or risk to the build sequence.

“Emery Industries demonstrated exceptional adaptability and punctuality, ensuring that all deliveries were executed on or ahead of schedule. Their willingness to adjust delivery timelines to sync with our construction milestones, coupled with their remarkable ability to accommodate last-minute user requests, was invaluable.”

Sam deGroen

Project Coordinator

Built Environs

The redevelopment of The Queen Elizabeth Hospital reflects South Australia’s commitment to delivering high-performance clinical care. Emery Industries is proud to have contributed to a project that not only expands emergency and surgical capacity but also sets a new standard for quality and efficiency in healthcare infrastructure.

Our stainless-steel solutions now support the daily workflow of sterile services teams, theatre staff and clinical operations—helping ensure that patients receive safe, reliable and consistent care within a world-class facility.