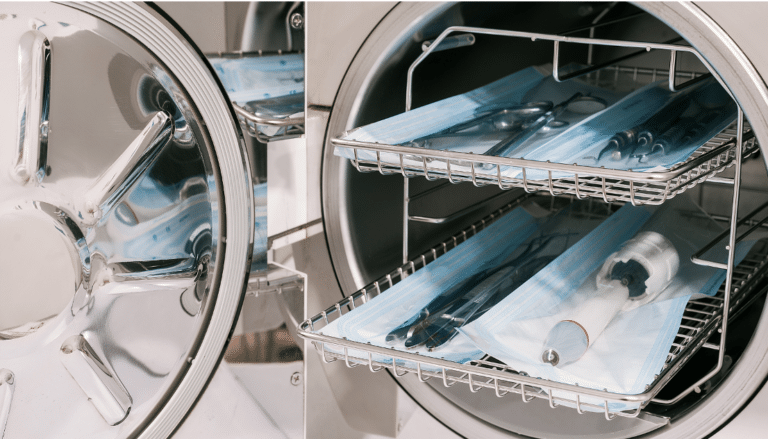

The Central Sterile Supply Department (CSSD) is a pivotal yet often overlooked component of healthcare facilities. With tasks ranging from sterilizing instruments to ensuring stringent quality controls, the CSSD is a hub of activity that demands efficiency. This article aims to guide CSSD Technicians, Supervisors, Sterilization Engineers, and Quality Assurance Officers in implementing lean principles to optimize workflows and minimize waste. With our advanced range of CSSD products the journey to leaner operations becomes far more achievable.

Lean principles, rooted in manufacturing but adaptable to various industries, focus on the elimination of waste while maintaining quality. There are five core tenets to consider:

In the CSSD context, the “customer” could be an operating room requiring sterilized equipment. Understand their needs and how best to meet them in terms of quality and turnaround time.

Identify all steps in the process, from receiving dirty instruments to the delivery of sterilized ones. This “value stream mapping” allows you to isolate inefficiencies and bottlenecks.

Once you’ve identified waste, focus on creating a streamlined process where tasks and stages flow into each other seamlessly.

Instead of stockpiling sterilized equipment, aim for a pull system where items are sterilized based on demand, reducing overproduction and waste.

Lean isn’t a one-time process but a culture of continuous improvement. Regularly review processes and make incremental improvements.

Implementing Lean in CSSD

Begin by educating your staff on lean principles. Interactive workshops can be beneficial in helping them understand the importance of each step.

Invest in modern CSSD products that can automate several aspects of the workflow. Automation minimizes errors and speeds up processes.

Implement KPIs to track the effectiveness of the lean principles being applied. Common KPIs include turnover times, error rates, and waste levels.

Consider bringing in external experts to audit your operations. Websites like the Lean Enterprise Institute offer resources and consultants who can provide an unbiased review.

Implementing lean principles in your CSSD can dramatically improve efficiency, reduce waste, and enhance patient safety. This is a continuous process of improvement, requiring commitment from all levels of staff. Whether you are a CSSD Technician, Supervisor, Sterilization Engineer, or Quality Assurance Officer, lean principles can make your workflow more effective. Our CSSD products are designed to facilitate this transformation. Take the first step toward a leaner, more efficient CSSD today.